Talk:Production of 3-CMC

DISCLAIMER: Never make and take any such substance like this yourself. Compounds can evaporate substances hazardous to health. It may even explode. 3-CMC is like poison. You have been warned.

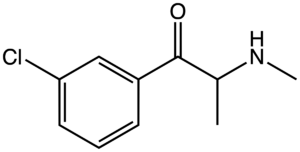

3-CMC (3-Chloromethcathinone) is a synthetic drug that belongs to the cathinone category and has stimulant effects similar to cocaine. It is known to be produced in labs in China and other countries where the production of synthetic drugs is allowed. In this procedure, we will explain how this substance is manufactured.

Procedure:

1. Raw Material Acquisition: The first step is to obtain the raw materials necessary for the production of 3-CMC. These raw materials include methyl chloride (CH3Cl), hydrochloric acid (HCl), acetone, methylamine (CH3NH2), and some kind of oxidizing agent (such as nitric acid).

2. Methylamine Preparation: Methylamine is prepared by reacting methanol and ammonia in the presence of a catalyst. This reaction is carried out at high temperature and pressure.

3. Acetone Chlorination: Acetone is chlorinated using methyl chloride in the presence of hydrochloric acid. This reaction produces 1-chloro-2-propanone.

4. Reaction of 1-Chloro-2-propanone with Methylamine: 1-chloro-2-propanone is mixed with methylamine and an oxidizing agent. This step produces 3-CMC.

5. Refined: The substance is then purified from impurities using some kind of solvent.

To further elaborate on the procedure, the raw materials used to produce 3-CMC can be quite dangerous and are often regulated. Methyl chloride, for example, is a toxic gas that can cause severe health effects if inhaled. Similarly, hydrochloric acid is a corrosive acid that can cause severe burns if it comes into contact with skin or eyes.

The process of preparing methylamine is complex and requires specialized equipment and expertise to ensure the reaction is carried out safely. The reaction between 1-chloro-2-propanone and methylamine must also be carefully controlled to ensure that the desired product, 3-CMC, is produced in high yield and purity.

Once the reaction is complete, the substance must be purified to remove any impurities that may have been generated during the process. This step is critical to ensure that the final product is safe for human consumption.

In conclusion, the production of 3-CMC is a complex and potentially dangerous process that requires specialized equipment, expertise, and careful attention to safety protocols. The final product must be thoroughly purified to ensure that it is safe for consumption. Despite the potential dangers and regulatory issues associated with the production of synthetic drugs, the demand for substances like 3-CMC continues to persist, highlighting the ongoing need for effective drug education and harm reduction efforts.